THE EXTRACTION OF METALS - AN INTRODUCTIONThis page looks at the various factors which influence the choice of method for extracting metals from their ores, including reduction by carbon, reduction by a reactive metal (like sodium or magnesium), and by electrolysis. Details for the extraction of aluminium, copper, iron and titanium are given in separate pages in this section. From ore to metalWhat are "ores"? An ore is any naturally-occurring source of a metal that you can economically extract the metal from. Aluminium, for example, is the most common metal in the Earth's crust, occurring in all sorts of minerals. However, it isn't economically worthwhile to extract it from most of these minerals. Instead, the usual ore of aluminium is bauxite - which contains from 50 - 70% of aluminium oxide. |

|||||||||||

|

Note: We always treat bauxite as if it was aluminium oxide for chemistry purposes, although it is actually more complicated than that in reality. |

|||||||||||

Copper is much rarer, but fortunately can be found in high-grade ores (ones containing a high percentage of copper) in particular places. Because copper is a valuable metal, it is also worth extracting it from low-grade ores as well. Ores are commonly oxides - for example:

. . . or sulphides - for example:

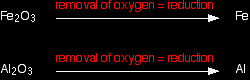

. . . and a whole lot of other things as well which we won't actually come across as a part of this topic for UK A level purposes. Concentrating the ore This simply means getting rid of as much of the unwanted rocky material as possible before the ore is converted into the metal. In some cases this is done chemically. For example, pure aluminium oxide is obtained from bauxite by a process involving a reaction with sodium hydroxide solution. This is described in detail on the aluminium page in this section. Some copper ores can be converted into copper(II) sulphate solution by leaving the crushed ore in contact with dilute sulphuric acid for a long time. Copper can then be extracted from the copper(II) sulphate solution. But, in many cases, it is possible to separate the metal compound from unwanted rocky material by physical means. A common example of this involves froth flotation. Froth flotation The ore is first crushed and then treated with something which will bind to the particles of the metal compound that you want and make those particles hydrophobic. "Hydrophobic" literally means "water fearing". In concentrating copper ores, for example, pine oil is often used. The pine oil binds to the copper compounds, but not to the unwanted rocky material. The treated ore is then put in a large bath of water containing a foaming agent (a soap or detergent of some kind), and air is blown through the mixture to make a lot of bubbles. Because they are water-repellent, the coated particles of the metal compound tend to be picked up by the air bubbles, float to the top of the bath, and are allowed to flow out over the sides. The rest of the rocky material stays in the bath. Reducing the metal compound to the metal Why is this reduction? At its simplest, where you are starting from metal oxides, the ore is being reduced because oxygen is being removed.

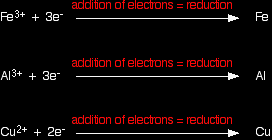

However, if you are starting with a sulphide ore, for example, that's not a lot of help! It is much more helpful to use the definition of reduction in terms of addition of electrons. To a reasonable approximation, you can think of these ores as containing positive metal ions. To convert them to the metal, you need to add electrons - reduction.

|

|||||||||||

|

Note: In some compounds the metal may not literally be present as a positive ion. Instead, it may be part of a covalent bond - but will always be the least electronegative element present, and so will carry some degree of positive charge. That means that its oxidation state will always be positive. Reducing that oxidation state to zero (in the raw element) will always involve adding electrons. If you aren't sure about oxidation states you could follow this link to find out about them. If you choose to follow this link, use the BACK button on your browser to return to this page later. |

|||||||||||

Choosing a method of reduction There are various economic factors you need to think about in choosing a method of reduction for a particular ore. These are all covered in detail on other pages in this section under the extractions of particular metals. What follows is a quick summary. You need to consider:

There may be various environmental considerations as well - some of which will have economic costs. Carbon reduction Carbon (as coke or charcoal) is cheap. It not only acts as a reducing agent, but it also acts as the fuel to provide heat for the process. However, in some cases (for example with aluminium) the temperature needed for carbon reduction is too high to be economic - so a different method has to be used. Carbon may also be left in the metal as an impurity. Sometimes this can be removed afterwards (for example, in the extraction of iron); sometimes it can't (for example in producing titanium), and a different method would have to be used in cases like this. Reduction using a more reactive metal Titanium is produced by reducing titanium(IV) chloride using a more reactive metal such as sodium or magnesium. As you will see if you read the page about titanium extraction, this is the only way of producing high purity metal.

The more reactive metal sodium releases electrons easily as it forms its ions:

These electrons are used to reduce the titanium(IV) chloride:

|

|||||||||||

|

Note: This is a good example of a reduction in which the metal isn't originally present as an ion. Titanium(IV) chloride is a covalent liquid. The reduction is from titanium in the +4 oxidation state to the metal in the zero oxidation state. |

|||||||||||

The downside of this is expense. You have first to extract (or to buy) the sodium or magnesium. The more reactive the metal is, the more difficult and expensive the extraction becomes. That means that you are having to use a very expensive reducing agent to extract the titanium. As you will see if you read the page about titanium extraction, there are other problems in its extraction which also add to the cost. Reduction by electrolysis This is a common extraction process for the more reactive metals - for example, for aluminium and metals above it in the electrochemical series. You may also come across it in other cases such as one method of extracting copper and in the purification of copper. During electrolysis, electrons are being added directly to the metal ions at the cathode (the negative electrode). The downside (particularly in the aluminium case) is the cost of the electricity. An advantage is that it can produce very pure metals.

To the Metal Extraction menu . . .

|

|||||||||||